Editor's Note: This article has been updated from its 2017 version.

Recently I was asked to meet a kind, older gentleman in our parking lot at the shop. This patient, old man wanted to speak with me regarding his 2008 Chrysler Town and Country. It seems he's been disappointed with the vehicle, as it has left him stranded several times here of late. I waited patiently as he told me quite a lengthy story regarding the entire history of this quirky failure.

I managed to extract from him is the vehicle fails to start intermittently. I asked him what he meant when he says, "won’t start." He made it clear when the key was turned to the "START" position, the starter would engage momentarily and quit shortly thereafter.

On many occasions, the battle to start the van would be on for well over an hour before the starter would remain engaged long enough to get the engine idling. He summoned me to the parking lot to demonstrate the issue for me. Unfortunately, the issue could not be reproduced, and this was the root cause of his frustration. This van has suffered from this erratic malfunction for well over a year.

He informed me that the starter has been replaced twice, as well as six ignition keys, two ignition switches and even two batteries! In fact, this malfunction occurred so erratically, any previous repair attempt would seem to fix the vehicle, but a few weeks later, the strange symptom reoccurred to his dismay. I assured him that if I could reproduce the concern while performing a series of tests, I should be able to isolate the malfunction and rectify the issue. Little did I realize how elusive this gremlin was going to be.

Start with a full system scan

I began my investigation with a DTC scan of the entire vehicle. To my surprise, there were absolutely none stored. After many attempts to reproduce the issue, I was disappointed to find that it cranked, started and ran each and every time I turned the ignition key to the "START" position.

I inspected the vehicle for aftermarket components with no suspects to condemn. I then chose to research TSBs and search Identifix for any similar failures (I like to go this route, especially when I have issues duplicating a complaint). Unfortunately, there were no offerings for me in either inquiry.

What to do next? I never feel comfortable pursuing an electrical issue unless I can reproduce a symptom of some sort, but basic tests like load testing of the battery and starting system are a must, especially in this case. Ruling out what isn’t wrong with the vehicle — early on in the diagnostic process — is just as valuable as finding the cause of the symptom the customer is experiencing.

Both the battery and starter circuitry showed no signs of failure or of any contribution to the peculiar malfunction this kind fellow was experiencing, for such a long period of time. As the afternoon came to a close, the gentleman assured me I could have the vehicle as long as I needed, so long as he could have it back with a confirmed fix. Tomorrow would be another opportunity.

I arrived at the shop Wednesday morning before 7 a.m. Typically, vehicles with issues like the one will be evaluated after the morning rush. I turned the key to remove the vehicle from the workshop, and to my surprise, the vehicle cranked for about 500ms before the starter ceased! I returned the key to the “Off” position and reattempted to start. The failure finally showed its ugly face.

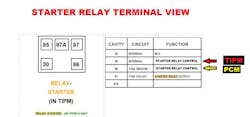

Since the issue was so elusive, I thought the best course of action may be to capture the actual fault right at the source (the starter circuit because it quits working) and work my way out of the hole. Looking at the wiring diagram, it’s easy to see that the starter relay is controlled by both the Totally Integrated Power Module (TIPM) and the PCM.

It’s time to do some research. I have to educate myself on the functionality of this starting system, as to avoid yet another misdiagnosis. To start troubleshooting at this point may prove to be a premature, costly mistake. It’s easy to feel unproductive if we aren’t hands-on working on the vehicle. Experience will show you that taking the time to devise a game plan and executing it will get you to the cause a lot more efficiently than rushing in without a plan of attack.

The TIPM energizes the starter relay coil by applying voltage to terminal No. 85. The PCM creates a ground path for the starter relay coil by driving the low side at terminal No. 86. Makes perfect sense.

Two computers control the starter relay, one at either end, but how do the respective ECUs know what to do and when to do it? Surely, we aren’t done researching yet. We still haven’t enough information to determine the total system functionality.

This required research of each individual component. Unfortunately, the description/ operation of the starting system as a whole was non-existent. Careful research was critical to solve this issue once and for all and without unnecessary part replacement.

Know what’s supposed to happen first

Not being familiar with this ‘08 Town and Country's total starting system functionality, I had to start researching at the beginning — at the turn of the key. The ignition switch is where I went. After all, I still couldn’t be sure if I was dealing with normal system operation during a security breach. Perhaps it was a "normal characteristic" to cancel starter operation?

As it turns out, the ignition switch is a lot more than just a switch. It's contained in another node known as a WIN module (or Wireless Ignition Node). This unit not only contains the ignition switch, but also stores info for the tire pressure monitoring system and queries the ignition key for the security system. The WIN has a self-contained ignition switch which is simply an input to the WIN.

When the WIN sees the ignition switch turned to the "Start" position and the key is valid, it will communicate the start “request” on the CAN bus to the TIPM. The TIPM will then output a voltage signal to the starter relay and simultaneously send a start request on the same CAN bus to the PCM. The PCM will respond and supply a ground path for the starter relay!

So now it’s time to build a game plan. I still want to begin my analysis at the high current side of the system (starter relay) where the work is performed. Although some may not agree with my initial test location, I know I experienced the starter energizing momentarily.

The method to my madness is to capture what is "disappearing" when the starter ceases its operation. I will, at that time, determine which direction to head in from there. I want simple access to the circuit, so I can gain a bunch of info for a small investment of time.

I removed the relay and wrapped the individual terminals with very thin wire. The idea is to allow me to test the relay in its normal location. By leaving the relay in this position, I've eliminated the chance of poor terminal contact in the fuse box, eluding my capture of the failure.

Now, take glance at Figure 1. The red trace is located at terminal No. 85 of the relay (the TIPM side), and the yellow trace is located at terminal No. 86 of the relay (the PCM side). As you can see, there are three distinct events on either trace:

1. A proper crank and start of the engine.

2. Shut the key off and crank the engine starts once again, without a hitch (If you look at the traces and imagine what is occurring, keeping in mind our test location and how the system operates, you can clearly see that the TIPM is supplying the voltage (red trace) and the PCM is supplying the ground (yellow trace)).

3. The yellow trace and the red trace have both been interrupted; the ground side of the circuit (yellow trace) has clearly risen/no longer being pulled low, and the voltage supply-side (red trace) drops off almost simultaneously.

Of course a failure on either side wouldn’t promote current flow through the relay coil windings and as a result, the starter would cease to operate. Could this be it? Could the failure be due to a problem on the PCM side of the system?

Perhaps, but remember, the PCM only does what it is told to do. It may have a failed driver or perhaps a poor B+/Ign/Ground feed. If that were the case, how do we explain a loss of supply voltage from the TIPM? There is also a possibility that the TIPM is telling the PCM to stop doing its job, too.

Now I have some ideas on where to look

Now, I have witnessed the failure through the eyes of a 2-trace lab scope and have determined that the both sides of the circuit seem to be experiencing a failure. It’s time to take a step back and do what is easiest. Since we've performed our due diligence, and we are aware that this system functions via the CAN bus, I've interfaced my scan tool and selected to watch the TIPM for the request for "Start" from the WIN.

During the time the failure was exhibited, the TIPM showed the crank request from the WIN the entire time I held the key in the "Start" position. Logic is telling me that the WIN is not the cause of the erratic starter operation because the TIPM never lost the command from the WIN. The PCM, however, may not be receiving the request from the TIPM during the failure. Unfortunately, after many attempts to monitor the PCM PID for crank-request, the failure just wouldn’t occur while I was watching (just my luck). I wasn’t ready to quit yet, though!

I chose to pinpoint my testing further than just at the relay terminals. I’ve elected to monitor the entire starter-circuit at multiple points utilizing my 8-trace labscope from Automotive Test Solutions. Some call it overkill, but I think John Anello said it best, "It’s like fishing with a net instead of a hook."

I have a lot of time into this diagnosis because the erratic failure is so infrequent. I would hate to have to test different sections of these circuits individually and take the chance of having the failure not show its ugly face, when I needed it to most!I want to show you a zoom of the failure-event.

In Figure 2, and you’ll see the brown trace (PCM) is being pulled low, shortly after-key-up, providing the ground path for the starter relay coil. About 250ms later, the purple trace is being driven high (TIPM) supplying the voltage to the relay coil. At that moment, you can see that the starter began to operate by the (CEMF) counter electromotive-force acting upon the circuit.

Voltage is hovering around 10V (fairly normal to what type of load a typical operating starter places on a battery). As you can see by the time of the scope-sweep, this starter operation lasted approximately 100ms before the TIPM ceased to energize the relay. What's more is, during this failure event, the PCM remained "low" and continued to do its Job.

In summary... the symptom of the failure remains the same (starter interruption), but the way the circuit failed is different from what we experienced earlier in Figure 1. It certainly appears now that the TIPM may be the cause of the issue.

How can I attribute the TIPM being at fault? A combination of my actual test results, and my newly attained knowledge of the system's configuration (the "players" involved in making the starter function). In Figure 1, both the TIPM and the PCM quit simultaneously. In Figure 2, the PCM remained functional. We know from the research we performed earlier, that the TIPM instructs the PCM to function.

Knowing that information, it's logical that the PCM quit because the TIPM told it tp. On the subsequent failure, the TIPM was the only guy to throw in the towel. In both cases, the TIPM is the culprit.

Module Or “PIG?”

Now, before I condemn any computer, I must first check on the "PIGs" (Power/Ignition/ground feeds). That is an abbreviation I used in the past to remind myself that a computer needs all three of these to function, just as I need water, food and oxygen to survive. Figure 3 shows a cranking event during failure while monitoring the PIGs at the PCM. The PCM has everything it needs to perform its duties.

I've just ruled out a supply issue of any kind for the PCM. The TIPM was much easier to test. Since the logic/computer is located inside the TIPM (internal to the fuse box), voltage supply is sourced internally.

Ground supply to the TIPM was sourced from five different terminals on three of the connectors, none of which lifted when the engine was cranking. A new TIPM was installed, and the customer’s concern was corrected.

Not all diagnoses are a walk in the park. Some take lots of research and much patience. Most can be deciphered fairly quickly with a combination of proper education, tooling, logic, information and a well carried out interrogation process. If all of these key ingredients are utilized, there are very few malfunctions that will eat your lunch.

I take tough finds like this one with me forever because these are the building blocks to proficiency and efficiency. Jobs like this one remind me why I love what I do so much, and why my employer keeps me in the payroll.