Earning an OEM certification is something many repairers have considered over the past 20 years. Some of the program members now have enough history to evaluate their return on investment, and the results have varied. Let’s look at the ways to evaluate the return on investment in membership of an OEM certification program, and if you do decide to renew or invest in an OEM certification, how to optimize the program’s features.

The History of OEM Programs

The OEM certification "body shop" programs have been commonplace post-war as most manufacturers rolled these programs out as part of dealer development programs. One of the most prevalent early programs was the Ford “Rotunda” program, which expanded dealer buying groups to aid in getting the most recent equipment in Ford dealerships.

These programs went through many changes in direction to collect more membership fees. The logic for the rising fees was to market this repair “network” to consumers and others to make the dealer shops stand out. Membership declined as dealers consolidated, they didn’t have a body shop, or their on-site body shop wasn’t large enough to justify the investment.

Having worked for a paint company, beginning in the 1980s they were asked by most OE manufacturers to pay certification fees. Initially, these fees were paid by those paint manufacturers supplying the OEM plants but later expanded to other paint lines as the products improved and the manufacturers increased the fee revenue generated. They rationalized that these fees were to verify the paint used in the aftermarket could withstand the warm and cold of North America. Generally, the OE manufacturer didn’t perform the testing; they asked the paint companies to pay a third party to verify the results and they had to be submitted with the “fees”, so they were kind of like a paint rebate program periodically helping them offset costs for other OEM sponsored programs.

Cost-cutting at the OE manufacturer level led to OEM program staff reduction and program changes which opened the door to OEM-certified paint manufacturer representatives being asked to perform OEM certifications. As the programs expanded and requirements grew, OE manufacturers have turned toward third-party companies contracted to perform the periodic inspections on the OE manufacturers behalf, gathering images of equipment and serial numbers and technician verification.

OEM Certification Expansion to Independent Shops

The most recent drive to expand membership and to get more vehicles repaired properly has led to these networks now being open to “independent shops” who were “sponsored” by an OEM dealer. A few organizations did some interesting research and found that many dealers lacked knowledge of their flagship manufacturers’ own OEM procedures.

It was during this most recent era many manufacturers started getting very specific regarding equipment requirements, in a way expanding the buying group logic dating back to Rotunda, by requiring a specific brand of tool. Frankly, repairers have implored OEM program leadership to instead provide list of equipment meeting their minimum requirements, so they could reduce their cost of membership by avoiding tool duplication.

A Key Change in Direction

With the newfound focus on these programs, OE manufacturers are now investing these fees to expand their OEM training centers and to improve the body shop-specific repair training. As a result, there has been a real focus certifying specific technicians to perform “safe and proper repairs” as part of the per shop certification process.

Further, as manufacturers such as Audi and JLR (and other premium brands) decided that the complexity of their vehicles had increased to a point where special equipment and training were needed, they could no longer justify selling certain structural parts to non-certified shops. “Right to Repair” advocates have fought to minimize these restrictions to encourage the free market for non-certified repairers and self-repair.

With the increased complexity of repair, repair training and promotion costs, the OE manufacturers have raised their certification membership fees. At the same time, the repairers have experienced a rising cost for the updated diagnostic, welding, riveting and other equipment required (also the clean room area and dedicated tooling for aluminum) and the specialized training required to repair the exponentially evolving complexity of vehicle repairs. The OE manufacturers have had to put more R&D time into repairability and clearly documenting OEM repair procedures to ensure the complex systems found in modern vehicles are repaired properly, and single-use fasteners and other items are recommended.

Evaluating the Return on Investment for an OEM Program

Quality assurance – The truly unspoken benefit for OEM-certification program membership is the training and resources available to an OEM-certified technician / repairer. Having easy access to the training center instructors and training on how to read the OEM repair methods does boost repair quality (less rework) and speed repair cycle time (due to reduced diagnostic time).

Increased Reimbursement Rates – Some innovative insurers have recognized the increased value in having consumers select an OEM-certified repair center for repair quality and speed. So, they have agreed to offer a slightly higher labor rate for repair time on those vehicle makes repaired. If that shop's flat rate is set no matter what the rate paid, the repairer would then be able to increase their labor gross profit (for example) from, say, 60% to 65% to help make up for the training and tooling investment.

Many repairers factor the improved quality and speed when they evaluate OEM repair programs, but we also need to consider the business math (labor rate change is excluded).

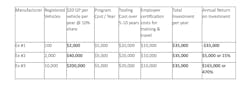

Potential Volume –The average consumer has a reported claim every 10 years. A conservative estimate of repair volume is $500 per vehicle per year at 40% gross profit. That means $200 in gross profit potential per vehicle in the market. Based on an example market share for a repairer being 10% of the vehicles in that market area, you could earn $20 per vehicle registered of a brand. This would obviously grow as market share grows:

Potential Volume for OEM Certification Programs

So, the key learning is to do homework on the program costs, and the opportunity to generate revenue prior to investing in (or as you evaluate your OEM program memberships).

There is a significant positive return for OEM program membership when you have enough vehicles registered in the area and/or you have earned a significant market share of those earned. The example above was calculated at 10% share, but we have seen 40-80% share for the premium brands, which affects the ROI calculation. So, marketing membership in these programs plays a major part in the ROI calculation.

A Few Ways to Drive Value for OEM Program Membership

- Your Company’s Brand Marketing – In any marketing piece produced, be sure to mention the OEM certifications earned and the benefit to customers for choosing an OEM-certified repair center.

- Dealer Marketing – If you are the dealer or have partnered with a dealer, then you may want to leverage their brand equity by encouraging them to put up posters in the service bays, add stickers in the glove boxes for new and used vehicles sold, ask them to mention your “Certified Collision Center” in ads they run or place.

- OE Manufacturer Resources – Prominently displaying the OEM certification plaque in your lobby can help, assuring your shop locator information is up to date on the OE manufacturer’s web site is helpful and often they provide “canned ads” which you can add your logo to for marketing.

- Virtual Lobby – Prominently display the OEM certifications earned and the reason that is valuable on your shop’s web site so potential customers consider that when considering where to call to schedule a repair.

- Phone Greeting – As your phone greeting script drives you to take control of the phone call and gather customer and vehicle data, train your CSRs and estimators to inform the customer if you are OEM-certified for their brand of vehicle and the value that certification offers.

- Inspection Meeting – Again, as the estimator inspects the vehicle, and notices it is a certified brand, explain the value OEM certification offers.

- Delivery / Post Delivery Marketing – At the time of delivery, be sure to mention the fact that you offer a lifetime warranty, and the OE manufacturer will also stand behind the parts used because you had an OEM-certified technician install them. This reassures them they made the right choice and might mention it to friends and family when they need collision repair.

Conclusion

OEM certification programs offer a lot of benefits to the consumer/insurer, the technicians, and the repair center, but it is up to the OEM-certified repairer to leverage those resources in market and selling efforts to optimize the return on investment.

About the Author

Steve Trapp

Steve Trapp is an internationally known consultant and speaker. His family operates a collision repair center in Wisconsin. He earned a degree in economics education and a minor in accounting from the University of Wisconsin.

After college, he worked for 3M in sales and marketing roles with the innovative 3M ARM$ training and software sales. He worked as a consultant for AutocheX doing financial consulting for a few years before joining AkzoNobel, where he started the industry’s first value-added program. While there, he started the industry’s first paint company-sponsored 20 groups and wrote numerous training programs with third-party experts on finance, marketing, selling, leadership, and other topics.

He later joined DuPont/Axalta, where he worked with Mike Anderson to manage their 20 groups and industry seminars. While at Axalta, he managed the North American Strategic Accounts SAM team and later the entire EMEA Strategic Accounts team. He followed that as senior consultant for LEAP, a global consulting firm that has presented in 10 countries and now again works for a major paint company.