No doubt emission concerns have changed the world. The modern vehicle is not exempt from these emission concerns. In fact, it is quite possibly the primary target of them. Any automotive technician can clearly see the effects of these emission concerns on a daily basis — from extended fluid changes, to tailpipe gas emission levels. It does not take much for one to understand that, considering the millions of vehicles in operation, these concerns are quite valid.

Tailpipe emission levels from millions of vehicles creates photochemical smog. Photochemical smog is a type of air pollution caused by chemical reactions that occur between the sun’s ultraviolet light and pollutants such as volatile organic compounds (hydrocarbons) and nitrogen oxides (NOx). This reaction produces airborne particles and ground-level ozone.

In southern California, air quality became an issue in the mid-1960s. In 1967, the state of California established the California Air Resource Board (CARB). CARB set emission regulations that were forced on the automotive industries to control the air quality for human health. At first, these regulations covered the internal combustion engine’s tailpipe and crankcase emissions and in 1970, moved to regulate the fuel containment system. In 1996, further emission legislation was implemented on the automotive industries that we know as On-Board Diagnostics II (OBDII). These OBDII regulations included engine misfire.

Misfire effects and OBDII

OBDII legislation regulates two different effects from engine misfire:

- An engine misfire that can damage the catalytic converter.

- An engine misfire that increases the tailpipe emission levels more than 1.5 percent over the Federal Test Procedure (FTP) standards.

Both of these engine misfire concerns will change depending on the engine operating conditions, such as engine load and engine speed. Under full engine load, the catalyst temperature threshold is set at approximately 1850°F; above this temperature, catalyst damage may occur. Therefore, misfire rates will be set according to the catalyst temperature.

For example, an engine running at 6000 rpm under WOT with an engine misfire rate of five percent may allow the catalyst temperature to exceed the threshold limit. However, at low load and low engine rpm, an engine misfire rate of 25 percent may be experienced before the threshold limit is hit. These engine misfire rates are only an example, as each engine is unique and will be calibrated for its particular engine misfire to catalyst temperature rates.

To calculate the engine misfire rates, the misfires must be accurately determined. There are several ways that the Engine Control Module (ECM) can monitor for engine misfire.

- One method uses ignition ion density to determine flame resistance in the spark plug gap. This is accomplished by providing a high energy output that is great enough to bridge the spark plug gap, thus bringing the temperature well past the auto-ignition temperature of the fuel stock. A secondary ion current is then produced that continues to bridge the spark plug gap. A signal processor then analyzes this ionization signal created by the detection circuit. This data provides useful ignition system data such as engine misfire, combustion duration, engine knocking, approximate air/fuel ratio, indications of spark plug fouling, and pre-ignition. This method is expensive and therefore not used in many vehicles

- Another method uses pressure sensors that are located in each of the cylinders. The cylinder pressure in an engine varies with the combustion of a fuel stock. By measuring the in-cylinder pressure a combustion event can be determined. To determine if a cylinder’s combustion was complete or incomplete, the pressure will be looked up in a table. This table provides normal pressures that should be produced for each of the engine operating ranges. These normal pressure ranges are then compared to the actual cylinder pressure that is currently produced by the pressure sensors. Additionally, the cylinder can be directly compared to other cylinders in a fire cycle. This method is expensive and difficult to implement in all engines and, therefore, rarely used.

Monitoring crank speed

The most common method uses crankshaft rotational velocity changes to determine combustion efficiency. This is accomplished using a trigger wheel (tone ring) that is made on, or attaches directly to, the crankshaft and a crankshaft position sensor. This trigger wheel is made of a ferrous metal that interacts with a magnetic field from the crankshaft sensor. This, in turn, produces a voltage output for each of the teeth on the trigger wheel in rotation. A waveform produced from one such trigger wheel is illustrated in Figure 1.

The trigger wheel can be made in many different configurations with different counts of teeth and different indexing points contained on the trigger wheel. If there is only one tooth for each cylinder, this is considered a low data trigger wheel. If the trigger wheel has many teeth, such as 36 teeth, this is considered a high data trigger wheel.

With more teeth contained on, the trigger wheel comes more resolution for better engine control. For example, if the trigger wheel contained 36 teeth, it would provide 10 degrees of resolution, whereas a 60-tooth wheel would provide 6.0 degrees of resolution.

As can be seen from Figure 1, the teeth on the trigger wheel produce a voltage output change based on the location of the teeth on the trigger wheel. These waveforms can be based on an analog voltage waveform or that of a digital waveform. Both types of waveforms are illustrated in Figure 1; waveform A is that of a digital voltage output, and waveform B is that of an analog voltage output.

The trigger wheel will have some method for indexing it to the crankshaft that allows the crankshaft position to be known. This crankshaft position will give the crankshaft’s plane locations in space. One such method is to have missing teeth located at some position around the wheel.

One example is a 36-tooth trigger wheel where one tooth is missing. The ECM uses this indexing information to identify the crankshaft position. The crankshaft position must be known to locate where the piston position is within the cylinder bore.

On a two-stroke internal combustion engine this is enough data since the fire cycle occurs each revolution of the crankshaft. However, this is not enough data on an Otto cycle four-stroke engine.

The Otto cycle engine has two complete crankshaft revolutions to complete the four engine strokes. Therefore, the use of just one sensor on the crankshaft would not provide the necessary data to calculate which of the engine strokes the engine is currently on. As the crankshaft rotates, it moves the piston toward the cylinder head until it reaches the Top Dead Center (TDC) point. It then moves the piston away from the cylinder head until it reaches the Bottom Dead Center (BDC) point.

The use of one sensor can only indicate if the piston is at TDC or BDC. It cannot differentiate which of the four strokes the engine is on. Therefore, a second sensor, or a trigger voltage, must be used to locate crank angle space. Crank angle space is where the particular engine stroke that the engine is currently on (intake, compression, power, exhaust) can be identified.

Where and how fast?

The ECM uses a second sensor to calculate the stroke identification. This sensor is known as the camshaft position sensor. This sensor provides the necessary data to accurately calculate the engine stroke location. The camshaft position sensor gives the data on the valve openings and valve closings. Thus, the particular stroke the cylinder is on can be calculated.

Once the engine stroke is known and the piston position is known, the internal combustion engine can now be controlled by the ECM. The ECM controls the engine, so it can produce power with the best tailpipe emission levels. The ECM provides the base engine control functions, which include the air/fuel delivery and the ignition discharge delivery (gasoline-based engines use the spark event while the diesel-based engines use the injection event). These controls are directly related to the four strokes of the engine.

Each of these engine strokes changes the crankshaft velocity. On the compression stroke, the volume of air contained in the cylinder is compressed. This requires energy from the engine to complete the compression stroke. The engine stores energy in the rotational mass of the engine. This mass carries the crankshaft rotation through the parasitic pumping losses of the internal combustion engine.

The strokes of the engine directly affect the crankshaft rotational speed. As the piston moves toward the cylinder head compressing the air volume contained within it, the crankshaft speed slows down. Then as the ignition event starts the combustion of the fuel stock, the crankshaft speed increases. By monitoring the crankshaft rotational velocity (speed), the combustion process of the fuel stock can be determined, thus a cylinder misfire can be determined.

For the original equipment manufacturers (OEM) to use this data from the crankshaft sensor and obtain the lowest probability of error, specialized electronic circuits are used. One such circuit is shown in Figure 2. This circuit modifies the voltage changes from the crankshaft sensor to a voltage level using a frequency to voltage converter.

This crankshaft data is then processed with a Discrete Fourier Transform algorithm. The Discrete Fourier Transform converts this signal into a point of frequency. This is then compared to an engine combustion model that is stored in the ECM.

Simple?

It is extremely difficult to locate misfires in an engine. The OEMs refer to this process as deconvolving the crankshaft angular velocity. If the crankshaft’s rotational speed is fast, then the time of the crankshaft slowing down and speeding up will be limited.

When the crankshaft is rotating at 6000 rpm, the fire cycle is only 20ms; therefore, each stroke is only taking 5ms to complete. The flywheel or torque converter stores this rotating energy within its mass and uses it to carry the crankshaft through its pumping losses. At high velocities, the crankshaft speed experiences very little change.

Additionally, the more cylinders that are contained within the engine, the less the crankshaft velocity changes, so it is easier to calculate the misfire data on a four-cylinder engine than it would be on a 12-cylinder. Therefore, the engine combustion model within the ECM must be accurately programmed to find misfires. Even if the model in the computer is correct, there can be problems with the misfire data process.

When these described methods or similar methods are utilized by the OEM and the misfires exceed a predetermined threshold, a Diagnostic Trouble Code (DTC) is set. This DTC indicates that the tailpipe emission has exceeded 1.5 percent of the Federal Test Procedure (FTP) standards or the catalyst temperature in the catalytic converter is too high. If the engine is misfiring but does not exceed the FTP, there may not be a DTC set. Ever experience this for yourself? You can feel an engine misfire occur but no stored or pending misfire codes are present.

If the engine is misfiring at a rate where it exceeded the FTP tailpipe emission level, a P0300 DTC can be set. A P0300 DTC indicates that a random misfire is present in the engine. However, this DTC is fairly useless to the technician. At slower crankshaft speeds the technician can feel the misfire, but they need to know which cylinder(s) are misfiring or having incomplete combustion events.

In some cases, the onboard computer can analyze the data incorrectly and set a DTC for the wrong cylinder. For example, a P0303 DTC is set in the ECM. The technician will now try to diagnose this DTC but it is for the wrong cylinder. The cylinder that is really misfiring is cylinder 5 or a P0305 DTC

Additionally, misfire DTCs can be set by other causes such as, but not limited to, the drive belt tensioner. When the drive belt tensioner clutch wears out, the tensioner begins to bounce. This changes the tension applied to the crankshaft, which, in turn, can change the crankshaft velocity — which may set false misfire DTCs. In some cases, the trigger wheel can become loose from the crankshaft, allowing the trigger wheel to move. This may also cause false misfire DTCs, as well as drivability concerns.

Additionally, if the crankshaft sensor itself becomes loose, it can vary the sensor output setting and also set false misfires as well as drivability concerns. When the data for the misfire is contained within the ECM, it is very difficult to know why the ECM is setting or not setting misfire DTCs.

What if?

What would be helpful is if the technician could test the same data; that is, the crankshaft sensor output, that the ECM is testing and setting or not setting DTCs for. This can be accomplished using an oscilloscope connected to the crankshaft position sensor with Channel 1 of the scope and connecting Channel 2 to an ignition event and then running the data through an incorporated algorithm.

In Figure 3, an engine crankshaft position sensor waveform with a misfiring cylinder is shown. This is the raw data gathered with an oscilloscope. No filtering or algorithm is being applied to the crankshaft position sensor waveform. This is what automotive technicians have been analyzing for over 40 years. As one can see, it is very difficult, if not impossible, to determine the crankshaft speed changes that occurred within this waveform. So, determining whether or not a misfire is present is not an easy task.

Figure 4 is the same data that is shown in Figure 3, except that an algorithm is now modifying this data. This unlocks the crankshaft velocity changes by using an advanced frequency plot algorithm, thus showing the combustion events that occurred or did not occur in the cylinders. Portions of the captured waveform are labeled "A", "B", and "C".

"A" is the point that the crankshaft speed reached its slowest speed, corresponding to TDC compression. "B" is where the crankshaft speed increased after firing the fuel stock and combusting it, accelerating the crankshaft speed. "C" is where the fuel stock did not combust, slowing the crankshaft speed. This crankshaft “slow down” indicates an incomplete combustion event.

The algorithm allows the crankshaft velocity changes to be seen; however, this does not identify the specific cylinder that created it. It will be necessary to have a second trigger present to find crank angle space as shown in Figure 5. This second trigger can be from any of the ignition coils for a gasoline engine or fuel injectors for a diesel engine. In this example, the coil from cylinder 1 is used.

Once a sync signal is provided, the crankshaft speed algorithm can be analyzed. This is accomplished by applying a grid or overlay that breaks the crankshaft waveform into the cylinders contained within the engine. In Figure 5, a firing order for the engine cylinders has been marked. These cylinder grids provide the divisions for each cylinder in the engine. So, for a three-cylinder engine there are three divisions, for a four-cylinder engine there are four divisions, for a five-cylinder engine there are five divisions, for a six-cylinder engine there are six divisions, for an eight-cylinder engine there are eight divisions, for a 10-cylinder engine there are 10 divisions, and so on. These divisions, along with a firing order for the engine, allows the individual cylinders to be identified. The cylinder grids are essential to divide the crankshaft sensor waveform into the number of engine cylinders contained in the engine under test so they can be analyzed.

When applying the cylinder grid it will be placed from trigger to trigger. Now a known firing order for the engine under test can be applied to the cylinder grid. When all of these items are accomplished, one can determine which cylinder(s) have incomplete combustion events. In this case, cylinder number 1 is missing. As can been seen, the crankshaft speed slowed down after coming to TDC compression. This indicates that the combustion of the fuel stock did not occur.

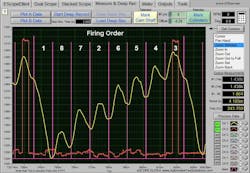

As seen in Figure 6, this method can be automatically accomplished. In the ATS Elite 4 and 8 trace scopes, this software allows an automated process which can identify which cylinder(s) have had a combustion event and which cylinders have not had a complete combustion event. In this example, a 6-cylinder engine is having incomplete combustion events. As can be visually seen, there are crankshaft speed changes that drop RPM on cylinder 3 and cylinder 2. The automated software has also determined that cylinder 3 and cylinder 2 are misfiring.

In Figure 7, there are multiple misfires occurring in time. When analyzing the data, the crankshaft RPM is evaluated both on the rise and fall. If the RPM rise rate does not increase with a large fall rate then the fuel stock did not fire. If the crankshaft RPM has a low rise rate and the fall rate is moderate then the fuel only partially combusted. If the rise rate is normal and the fall rate is normal then the fuel had a complete combustion event.

This technique will not work at higher RPM but works well at lower RPM. This is a quick way to verify the combustion events that are occurring within the cylinders of an engine. Additionally, this can help to diagnose both gasoline-based engines and diesel-based engines. You will find that this technique is a great help with many of your engine diagnostics.

About the Author

Bernie Thompson

Contributing Editor

Bernie Thompson is an accomplished automotive diagnostician and trainer, and is also the co-founder of Automotive Test Solutions (ATS) based in Albuquerque, New Mexico. He has over 40 years of experience in automotive gasoline and diesel repair. Over twenty years of experience in design, engineering, and fabrication of automotive diagnostic equipment. Mr. Thompson holds; 22 US patents, 1 European patent, 1 Canadian patent, with 22 U.S. patents pending, 3 European patents pending, and 3 Canadian patents pending. Additionally Mr. Thompson writes automotive training curriculum for the automotive industry, is an editorial contributor for Motor Magazine, Motor Age Magazine, and has co-authored an SAE paper. Thompson also teaches advanced automotive diagnostic curriculum internationally. Connect with Thompson on the ATS Facebook page.