OEM procedures, calibration more important than ever

Content brought to you by ABRN. To subscribe, click here.

What you will learn:

- According to the "2021 Who Pays for What? Scanning & Calibration" survey from Mike Anderson’s Collision Advice and CRASH Network, 59 percent of respondents say they research OEM repair procedures “all or most of the time,” compared to 42.7 percent in 2015

- Nearly three-quarters (73.4 percent) of respondents say they use ALLDATA compared to 52.8 percent that use OEM information websites, 46.44 percent that use I-CAR, 43.4 percent that use CCC, and 13 percent that use Mitchell

- Now that ADAS technology is standard on virtually all new vehicles, shops need quick access to ADAS information in order to see the extent of OEM-required calibration and whether they can perform the procedures in-house or need to sublet

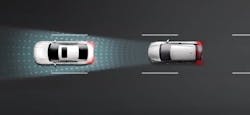

A successful repair starts with the right parts, the right training, the proper equipment, and an understanding of the latest repair procedures. As vehicles on the road today become more and more sophisticated with advanced driver assistance systems (ADAS), lidar-based autonomous driving systems, and other new technology, the proper OEM repair and calibration procedures have become ever more important (Figure 1).

How often are body shops accessing OEM information?

According to the "2021 Who Pays for What? Scanning & Calibration" survey from Mike Anderson’s Collision Advice and CRASH Network, 59 percent of respondents say they research OEM repair procedures “all or most of the time,” compared to 42.7 percent in 2015. As vehicles become increasingly complex, this trend reflects the industry’s focus on the absolute necessity of following OEM procedures for safe and accurate vehicle repairs, and to limit liability. Nearly three-quarters (73.4 percent) of respondents say they use ALLDATA compared to 52.8 percent that use OEM information websites, 46.44 percent that use I-CAR, 43.4 percent that use CCC, and 13 percent that use Mitchell.

Does anyone combine information from multiple OEMs into one subscription?

Many OEMs also license their data to companies such as ALLDATA, RepairLogic, CCC, and Mitchell that provide OEM repair information for the vast majority of vehicles on the road today. For example, ALLDATA's collision repair software delivers unedited OEM data targeted specifically to auto body repair shops, including body and frame sectioning, handling of new materials, evolving technologies such as hybrids and panel replacement, manufacturer position statements, DTCs, TSBs, color wiring diagrams, and a new ADAS Quick Reference tool.

Where can I get ADAS information?

Now that ADAS technology is standard on virtually all new vehicles, shops need quick access to ADAS information in order to see the extent of OEM-required calibration and whether they can perform the procedures in-house or need to sublet.

ADAS features are designed to provide a safer, more comfortable, and more convenient ride. All these systems use a complex variety of sensors and firmware, and each OEM has their own procedures for handling the repairs. That’s another reason it’s crucial to follow each manufacturer’s procedures and know exactly where the sensors and cameras are located. Even a seemingly run-of-the-mill repair could cause one or more sensors/cameras to become misaligned. Choose a repair information provider with easy access to ADAS information, such as OEM1Stop.com to get the job done faster and easier.

What is a position statement?

Position statements (Figure 2) are provided by OEMs, stating what the OEM allows or disallows on specific repair procedures and parts usage. Position statements are generally available at no charge directly from OEMs. For Nissan, they are available on partsadvantage.nissanusa.com. Nissan, and many other OEM position statements can also be found at OEM1Stop.com. Some examples of recent position statements include:

- Pre and post diagnostic scanning during collision repair from Ford.

- Importance of using Volvo-approved adhesives.

- Use of aftermarket substitute parts on Subaru vehicles.

What about single-use parts?

Designated single-use parts are designed for installation-only purposes and should be discarded once removed. While these parts may be absent of related damages, the reuse of such parts may cause repair issues and compromise the quality and safety of the vehicle. Stationary glass, safety restraint systems, mechanical components, fasteners, clips, bolts, screws, or interior trim pieces may fall into this category. Check the OEM service manuals to help identify these parts.

What are some training resources?

There are many training resources out there for collision repair technicians depending on which OEM they are interested in receiving training on.

Nissan and Infiniti offer a Collision Estimating Essentials virtual course. It’s an in-depth look at the proper estimating procedures needed for today’s increasingly complex vehicles. Nissan also offers a 45-minute Nissan and Infiniti Intelligent Mobility Technologies course that provides an overview of the technologies and components used by Nissan and Infiniti to monitor, respond, and protect passengers while driving.

Toyota's Collision Repair & Refinish Training offers a wide variety of curses including advanced painting techniques, structural body repair techniques, and using the OEM's technical information system (TIS) for collision repair.

BMW offers a Body and Paint Service Technician Education Program (STEP) that covers all aspects of body and paint repair in a nine-month program.

Check with each individual OEM to see any repair procedure training, videos, or webinars they may offer.

Written with additional files from ALLDATA.