Over the past few years, we have been asked to assist shops in implementing scheduling systems. So many people are afraid to lose work, so they just take the work in and deal with the repercussions. First, we will discuss planning based on forecasted sales and capacity and then we will address scheduling logistics and finally we will address some of the customer concerns.

Prior Planning

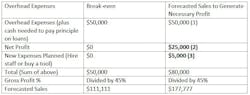

Based on the number of working days in a month, most repairers have an idea of what their sales forecast might be. To get started, we work with them to calculate their break-even and forecasted sales level to generate the profit they need to operate. In the box below we consider their current overhead ($50,000 = #1) and in the 3rd column we added desired net profit ($25,000 = #2) and consider a new one-time expense for the month ($5,000 = #3). The result is that we need to schedule for $177,777 volume for the following month.

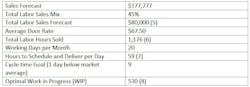

This is where most people tend to stop. Instead, we attempt to determine the daily hours to schedule and even determine an optimal WIP. We take the forecasted sales times the total labor sales mix to determine the number of labor dollars needed to achieve the goal. Simply dividing the $80,000 (#5) by the current average door rate will tell us the total labor hours we need to produce in a month (1,176 = #6) to achieve the $177,777 in forecasted sales. Dividing that by the number of working days in the following month produces the all-important number of total hours to schedule and deliver every day (59 = #7)!

Next, we determine the optimal work in progress (WIP) level by taking your shop’s cycle time goal in days times the hours per day (59 * 9 = 530 total hours = #8), which yields the optimal WIP for this location. Once that number is known, we monitor this each day at our morning release meeting and adjust the incoming schedule accordingly.

Next, you need to level out the schedule and assure that you are bringing in only 59 hours per day, or no more than 295 (59 X 5 days) per week. The goal is to never exceed the optimal WIP of work in the shop of 530 hours of total labor for the facility to raise the repair cycle time above the market average. Vehicles which are in the “hospital” or for some reason cannot be worked on due to approval delays, parts availability, or other reason, do not count toward optimal WIP.

Implementing a Lean Schedule

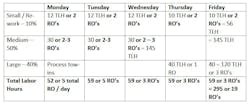

After you consider your technicians’ capabilities, you need to establish what percentage of the capacity you are going to invest in each type of work. The most productive weeks this shop has had, they process approximately 40% as large / tow-in or heavy hit (over 30 hours), 10% small jobs (less than 6 hours) and 50% medium-sized jobs (7- 30 hours). You will have to adjust this based on your technicians’ capabilities.

The work is spread out where the medium jobs, which should be completed during the week, are scheduled on Monday and Tuesday. Mix in small jobs each day, so those “zero-day” repairs can be completed in the same day as they are dropped off, or at most in two days. Tow-ins are dealt with on Monday but scheduled in for repair planning / blueprinting or disassemble-for-repair (DFR) later in the week. This levels the work out in the repair planning area throughout the week. Any repair planning on small jobs should be done first each day. Those scheduled drop-off appointments should be the earliest in the morning:

Additional Scheduling Tips:

-

Attempt to schedule starting with Thursday or Friday of the week and then fill in Monday to Wednesday as the job size and customer need dictates.

-

For medium hits where you haven’t done a physical inspection, estimate them at or near 20 total labor hours until you repair-plan.

-

For heavy hits or tow-ins where you haven’t done a thorough repair plan, estimate these jobs at 40 hours, and adjust once the repair plan is complete.

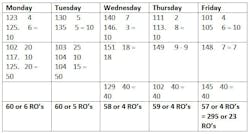

Below is a real-life example of a shop schedule using this method. As you will note, the mix wasn’t as perfect as planned, but we stayed to the 295 total hour goal. And as you schedule repairs, log the RO number and note the actual hours sold on a physical board or within your management system to try to stay to the 59 hours per day or per job size numbers.

How do we overcome consumer objections of not being able to drop off immediately, or bringing their vehicle on later in the week?

-

We try to schedule a few one-two day repairs later in the week so we can keep that team focused on zero-day or two-day repairs.

-

Bring in most profitable medium sized repairs early in week in premium slots and attempt to complete them in three to five days to avoid weekend rental days.

-

Set the expectations with larger repairs that we will be keeping the vehicle for a few weeks, so starting later in the week ensures we keep working on the vehicle once we start on it.

-

To bring in smaller repairs later in the week, which may roll over a weekend, we can encourage customer-paid repairs by having a higher door rate for those repairs but offer a discount for coming in later in the week when our fast-track repair team has capacity.

The keys to scheduling are quite simple. Set a reasonable forecast to ensure you make a profit. Once you know your daily sales goal, calculate optimal WIP and modify your daily schedule to ensure you don’t have too much (or too little) work on site. The true art is leveling intake of work daily to a target. Another art is bringing in the right mix of work throughout the week and balancing the volume of intake and delivery to level the workload of your team.

Scheduling is an art, but it’s not an impossible science if you apply these guardrails to keep your Estimators and CSRs on track when scheduling.

About the Author

Steve Trapp

Steve Trapp is an internationally known consultant and speaker. His family operates a collision repair center in Wisconsin. He earned a degree in economics education and a minor in accounting from the University of Wisconsin.

After college, he worked for 3M in sales and marketing roles with the innovative 3M ARM$ training and software sales. He worked as a consultant for AutocheX doing financial consulting for a few years before joining AkzoNobel, where he started the industry’s first value-added program. While there, he started the industry’s first paint company-sponsored 20 groups and wrote numerous training programs with third-party experts on finance, marketing, selling, leadership, and other topics.

He later joined DuPont/Axalta, where he worked with Mike Anderson to manage their 20 groups and industry seminars. While at Axalta, he managed the North American Strategic Accounts SAM team and later the entire EMEA Strategic Accounts team. He followed that as senior consultant for LEAP, a global consulting firm that has presented in 10 countries and now again works for a major paint company.