Content brought to you by ABRN. To subscribe click here.

What you will learn:

• Gaseous vehicle usage seems to be tied mostly to cost of fuel and used mostly by fleets and municipalities

• Natural gas powers over 175,000 vehicles in the United States and propane about 60,000 vehicles

• Propane has been in use since the 1920s as fuel for light-duty and heavy-duty vehicles

Following the groundwork of the previously published article on electric cars and collision repair, we will now move on to another alternative fuel vehicle classification, specifically gaseous fueled vehicles.

Gaseous vehicles can be categorized into three types of fuel: propane, natural gas, and hydrogen. Today, we'll leave hydrogen fuel cell vehicles for a future article and focus instead on propane and natural gas.

Natural gas- and propane-powered vehicles have been in existence for decades, but they can't seem to get out of the starting gate. Their popularity has ebbed and flowed throughout the 2000s, with usage seemingly tied directly to the cost of gasoline and diesel. When gas prices go up, everyone rushes to less expensive fuels such as the gaseous ones, and the opposite happens when gas prices drop. However, even during periods when gaseous fuel vehicles were the most popular, their use was primarily represented by fleets and municipalities. Why the lack of adoption from the light-duty consumer? It’s mainly due to the lack of fueling infrastructure; consumers are not likely to purchase an alternative fuel grocery-getter if they aren't confident in their ability to put fuel in the tank.

Looking at medium and heavy duty gaseous fuel vehicle usage, their popularity has stayed relatively consistent for non-consumer fleets. According to the U.S. Department of Energy's Alternative Fuel Data Center, natural gas powers over 175,000 vehicles in the United States and propane about 60,000. Those are not very large numbers for a country with just shy of 290 million cars on our roadways, but there has been steady growth. They are a wise choice for fleets with large fuel usage volumes to justify the cost of installing propane or natural gas fueling stations.

Although propane and natural gas are somewhat similar in how they are used as a vehicle fuel and are frequently grouped together (like in this article), they are distinctly different. Therefore, this article will discuss each separately, presenting the capabilities of each along with their advantages and disadvantages.

Natural gas

Natural gas can be used as a vehicle fuel in two different forms: compressed natural gas (CNG) and liquefied natural gas (LNG). LNG is mainly used in over-the-road trucking and is somewhat limited in its current implementation and will not be referenced in this article.

Compressed natural gas is named correctly. CNG vehicles have a fuel tank that holds natural gas compressed to a maximum pressure of 3,600 psi to give the best range possible for the size of the fuel tank the vehicle may have. With most commercial fueling stations, they can fill their tanks almost as fast as a gasoline vehicle, but these "fast-fill" stations are costly, with large implementations costing millions of dollars. However, for operations with a fixed usage cycle, such as refuse trucks and "point-to-point" deliveries, a less expensive fueling structure commonly referred to as "time-fill" can refuel the vehicle overnight while the vehicle is not in operation.

Natural gas fuel system types

There are three variations of CNG fueling systems ideal for different situations: dedicated, bi-fuel, and dual-fuel.

- Dedicated: Vehicles that operate on only one fuel, natural gas

- Bi-fuel: Vehicles that have two separate parallel fueling systems, enabling them to run on either natural gas or gasoline

- Dual-fuel: A heavy-duty truck fueling system that operates on diesel but "blends" natural gas with the diesel for lower emissions and fuel cost

As you can readily see, each of these fuel system configurations has an ideal segment in the transportation market. A dedicated system will give the vehicle operator the most extensive fuel-saving opportunities as they operate on CNG only. A bi-fuel system would be ideal for a vehicle that works in areas where there may or may not be CNG fueling available and can then operate on gasoline until CNG is available. Dual-fuel research and testing are ongoing for the heavy-duty tractor-trailer market. These vehicles blend CNG and diesel in a conventional compression ignited diesel engine, replacing as much diesel as possible with a lower-cost and cleaner-burning gaseous fuel.

Propane vehicles

Propane is a colorless, odorless heavier-than-air gas that, when compressed, can be stored as a liquid. Liquefied petroleum gas (LPG), commonly referred to as propane, is a high-energy alternative fuel familiar to most people, especially those who use it to heat their homes. However, propane can be used for more than just home heating and cooking. Propane has been in use since the 1920s as fuel for light-duty and heavy-duty vehicles. Today, three percent of propane produced is used as a transportation fuel. Nearly all of the United States' propane is produced domestically. More than half (55 percent) of the propane produced is a byproduct from natural gas purification from wet gas wells, and the rest (45 percent) from crude oil refining.

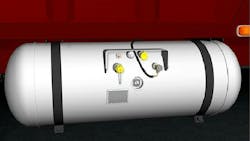

When stored in a vehicle as fuel, propane is contained at a relatively low pressure of 170 psi, or about twice the pressure of a tractor-trailer truck tire. Compared to other gaseous fuels, this relatively low pressure gives propane an advantage, as vehicle fueling stations are relatively inexpensive to install, and vehicles using propane can be fueled quickly.

Although there are no light-duty propane vehicles available directly from an original equipment manufacturer (as far as I know), many aftermarket conversion companies convert gasoline vehicles to partial or total operation on propane. In addition, companies such as ICOM North America and Alliance AutoGas produce and sell EPA and CARB-certified conversion kits for all types of transportation equipment that can be installed in-house with a bit of training.

Propane fuel system types

Like natural gas, there are three variations of propane fueling systems ideal for different situations: dedicated, bi-fuel, and dual-fuel.

- Dedicated: Vehicles that operate on only one fuel, propane

- Bi-fuel: Vehicles that have two separate parallel fueling systems, enabling them to run on either propane or gasoline

- Dual-fuel: A heavy-duty truck fueling system that operates on diesel but "blends" propane with the diesel for lower emissions and fuel cost

Again, just like natural gas, each of these fuel systems has an ideal segment in the transportation market. Unless a vehicle purchaser has direct access to a propane fueling station, most operators choose the bi-fuel configuration to prevent the "range anxiety" of seeking a propane fueling station when running low. In addition, the dual-fuel systems are explicitly used in the class 8 tractor-trailers to replace diesel in compression ignited engines, reducing emissions and lowering fuel costs.

Gaseous vehicle repair

Like a firefighter arriving at the scene of an accident, a collision repair shop should recognize the type of vehicle they are repairing. Relying on the consumer or the referral shop to correctly define the type of vehicle you will be servicing is no longer an option. Recognizing propane or natural gas vehicle for what it is immediately upon its arrival at your facility is the first step in its effective and safe repair. Industry-standard labels can often identify gaseous fuel vehicles but should not be relied upon as the sole method of vehicle identification. Looking at the vehicle's fueling ports, checking for non-standard gauges on the dashboard, and examining the type of fuel tanks located in the vehicle are other ways of recognizing the type of fueling system on a vehicle.

Once a vehicle has been recognized as a gaseous fuel vehicle, a good practice for all shops is to label it as such. Using a grease pencil to write "propane" or "CNG" on the front and rear glass, placing a bright red hangtag on the wiper arm, or simply taping a piece of paper to the hood clearly labeling a gaseous fuel vehicle as it enters your shop is a best practice everyone should follow. This label will inform everyone, from the service writer to the detail crew, that a non-standard fuel system is present in the vehicle, laying the groundwork for a safe vehicle repair pathway.

Training. It always starts with training. If the reader gains one thing from this article, it should be for them to seek out training on how gaseous fuel vehicles operate, gain knowledge on their specialized fuel system components, and, most importantly, learn how to correctly and safely disable the vehicle and prepare it for safe collision repair work. Unlike electric cars, most light-duty and a good portion of medium and heavy-duty gaseous fuel vehicles are upfitted by third-party companies. Very few are produced directly from OEM vehicle companies, which makes consistency in their fuel system a challenge.

A great place to start to acquire information on a gaseous fuel vehicle is from the vehicle's repair and safety information. Automotive upfitters and manufacturers offer vast knowledge on all vehicles, including their gaseous fuel products. There are also many third-party organizations that provide training, much of which can be accessed online, including the one for which I am director of education, AFV Educate.

Collision repair guidelines – propane vehicles

It is hopefully a given that this article should not be used as a replacement for quality training. It is designed to give the collision repair technician an overview of the unique structure and associated techniques needed to repair propane vehicles and provide them with a launch pad to pursue quality training for proper collision repair.

A technician new to propane vehicles needs to know that they are identical to gas or diesel-powered vehicles other than the fuel tank and fuel delivery system. Propane vehicles still possess an internal combustion engine, a 12V electrical system, and a conventional driveline, including transmission or transaxle. Therefore, the primary focus of working with a propane vehicle in a collision repair shop will be dealing with the fuel tank and the fuel it contains.

The vehicle's fuel tank must be defueled of all fuel and the tank purged of any residual gas before repair work can begin. An alternative to defueling the tank would be to remove the tank entirely from the vehicle. Once the fuel has been removed from the tank or the tank taken from the vehicle, the collision repair process can proceed, including conventional paint curing. The defueling process or safe removal of the propane fuel tank requires specific tools, systems, and training as defined by codes and standards, including environmental guidelines. Therefore, fuel handling is the prime topic that a collision repair specialist should seek training on. Unlike liquid vehicle fuels, a gaseous fuel leak can be extremely dangerous to those working around it and the building where the vehicle is being repaired. Propane gas is heavier than air, and a fuel leak can allow the gas to congregate in low-lying areas such as repair pits, drains, and basements where a spark from a tool, welder, or even a refrigerator can cause a catastrophic explosion. Understanding the vehicle and the fuel is why quality training is required before addressing the repair of gaseous-fueled vehicles.

Before moving into gaseous fuel vehicle repair, a collision shop should also research local building codes and standards to determine structural repair facility requirements for gaseous fuel storage, ventilation, electrical systems, and other applicable local or national guidelines.

Collision repair guidelines – natural gas vehicles

The above information on natural gas vehicles also applies to CNG vehicles, with one crucial additional guideline. Natural gas fuel tanks are primarily constructed of a fiber wound cylinder tank that can be filled with natural gas up to 3,000 psi. and are not as robust as the solid steel propane tanks found in propane vehicles. Therefore, there are national standards for the inspection of CNG vehicle fuel tanks if the vehicle has been involved in an automotive incident, fire, or every three years or 36,000 miles. There have been tragic incidents, including loss of life, when a defective CNG fuel tank was put back into service after collision repair without inspection when a damaged tank exploded when being filled.

Expanding your capabilities to cover work on gaseous vehicles can bring a new stream of work into your shop. Look at your local municipality fleets, airport buses, taxi companies, or refuse trucks, and you might be surprised to see many of them operating on propane or CNG. They are involved in incidents just like any other type of vehicle, and they could bring revenue to your business.

About the Author

Micheal Smyth

Micheal Smyth is a founding partner and Director of Training for AFV Educate, a not-for-profit 401(c)(3) training organization specializing in alternative fuel curriculum development and educational presentation for first and second responders and automotive technicians. His previous positions included Director of West Virginia University’s National Alternative Fuels Training Consortium and Director of Training at Automotive Video Innovations. Mike has over 12 years of experience working with and presenting information on AFVs. Connect with him at LinkedIn.