Bumper repair: Stay away from the sensors

What you will learn:

• ADAS reduces fatalities and will be present on all most vehicles

• Many individual systems and technologies make up ADAS

• Refinishing practices are crucial to proper ADAS functionality

Content brought to you by Auto Body Repair Network. To subscribe, click here.

In their drive to reduce the number of road injuries and fatalities, the OEMs have laudably been making collision avoidance technology which used to be the preserve of higher-end vehicles standard all the way through the product line down to their entry level vehicles. For this reason, collision repairers will be seeing more and more sensors on late-model vehicles.

Most sensors will be found at the front and rear of the vehicle. Although Lidar and other advanced sensors will be on their way later in the decade, for now, you will find two major families of sensors – sonar and radar.

Sonar-based sensors are the round ones about the size of a penny that protrude through the bumper fascia. These are short-distance proximity sensors that use sound waves to measure the distance to objects near the vehicle. These are typically used for parking sensors. Doing a repair on the bumper fascia near a sonar-based sensor is not a problem because the sensor itself protrudes through the bumper.

Radar-based sensors are more powerful and are used to sense objects farther away. On the front of the vehicle, radar is used for adaptive cruise control and autonomous emergency braking, among other things. Radar-based sensors on the rear of the vehicle are used for blind spot and cross-traffic monitoring. These are typically mounted behind the bumper fascia and project their signals through it.

Considering any radar-based sensor which passes its signals through the plastic bumper fascia, understandably the OEMs are wary of anything which might affect the signal in either direction. For this reason, most OEMs prohibit refinish or repair operations in the general area of the bumper around where the sensors are mounted. Some OEMs even go so far as to prohibit any repair or refinish operations done anywhere on the bumper.

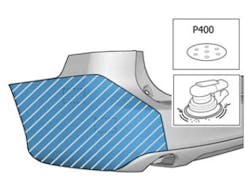

What should the collision repairer do? First of all, research the OEM’s repair procedures to see what areas of the bumper fascia are affected by a repair prohibition. In most cases, there will be a dimensioned diagram showing the area that cannot be repaired, such as shown in this image of a Volvo rear bumper.

If the OEM procedures are not clear, then use your judgment. If there is a radar-based sensor behind the bumper fascia in the damaged area, it would be best to replace the bumper. Any material used which increases the thickness of the bumper in the damaged area will certainly affect the signals being sent and received by the sensor. This includes plastic welding rod, metal reinforcing mesh, adhesives, fillers, and refinish coatings.

If the OEM procedures allow repair in the damaged area, or if the damage is in an area well away from any underlying radar sensors, then a safe repair may be performed. Plastic repair can be performed using any number of methods, from welding to adhesives, depending on the skill, experience, equipment, and consumables available to the collision repair technician.

The bottom line is, when considering a plastic repair on a bumper fascia with radar-based sensors mounted behind, first follow the OEM procedures, and if those aren’t clear, stay away from the sensors!

About the Author

Kurt Lammon

President, Polyvance

Kurt Lammon, president of Polyvance since 1995, has a bachelor's degree in mechanical engineering and a minor in material science. He has been focused on developing and manufacturing products to help auto body technicians and DIY-ers repair damaged plastic parts. Polyvance has specialized in plastic repair products since 1981. The company was founded as Urethane Supply Company by Jim Sparks who invented the original airless plastic welder to repair the thermoset polyurethane bumpers that were popular in the '70s and '80s. Since that time, the company has introduced several innovations, including the Uni-Weld FiberFlex universal welding rod, Bumper & Cladding Coat Adhesion Primer, and the Nitro-Fuzer nitrogen plastic welding system. Polyvance is an I-CAR Sustaining Partner and provides several hands-on and virtual training courses on plastic repair and refinishing.