Advanced technologies: safety and electronically controlled ride dampers

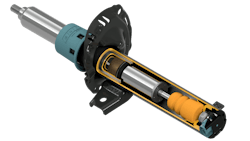

As vehicle manufacturers continue to improve safety as well as ride comfort and handling capabilities, advanced technologies are being added to model lineups. Subject Matter Experts from I-CAR’s Repairability Technical Support (RTS) team discuss vehicle ride control through the use of electronically controlled shock absorbers and struts. Variable viscosity fluid and valve type methods also will be discussed as well as repair and diagnostic considerations.

I-CAR Subject Matter Experts:

Bud Center, Director, Technical Products and Curriculum

Dirk Fuchs, Director, Technical Products and Services

Jeff Poole, Manager, Subject Matter Expert

Scott Van Hulle, Manager, Repairability Technical Support and OEM Technical Relations

The complete panel video can be found here.

Center: In today’s vehicles, we have what’s termed as electronically controlled suspensions. What are some of the options that are out there?

Fuchs: In the 90’s, the Formula 1 racing cars were starting to develop electrical shock absorbers and the problem was that the G-force was so high that that the driver passed out. That's the benefit of electrical controlled systems; you can control the shock absorber in the moment it’s needed. That’s what we want now in a regular car, of course. But we want to give the driver as much comfort and safety as possible while taking a corner or when facing a dangerous situation to stabilize the vehicle. One option is valve control, where we're controlling the valve, opening and closing it to make the shock absorber harder or softer. We want to drive comfortably, but we might need to make a quick move if a child runs onto the street with a ball and you have to react quickly. We’ll want to control the chassis and have it as stiff as possible.

So electrical valve control is one option, or we can control the fluid. You can control the viscosity of a fluid to make the viscosity higher or lower to control the ride of a vehicle.

Poole: Most folks have heard the term MagneRide. I have a small amount of that fluid in this container, and it has a very low viscosity. It's very thin. And now that I've coated the inside of that container you really can't tell, but it's thicker than water, but I'll say right now it's about 10 weight oil.

I have some of the same fluid in this Petri dish with a magnet on the bottom. With the magnet on the bottom, it gets that fluid to basically increase its viscosity, drawing up to where it is essentially thicker. And the beauty of this is that while I've got a permanent magnet on the bottom of my Petri dish, it can be electronically controlled very quickly.

The concept behind this is what I have on the table in front of me, where I have basically just two syringes. Imagine that one of the syringes represents the upper chamber in your shock, or the lower chamber, and the other syringe represents the other chamber and where you're exercising that shock absorber, that fluid's going through a fixed orifice. If that area where the fluid has to travel has an electromagnet around it, and this is just a coil of wire here and much larger than what's in the actual shock, as we're driving down the road and that shock absorber operates, we could very quickly electrically charge the coil. And what's neat about it is that the vehicle systems can (extremely quickly), alter the amount of electromagnetic field around those orifices in order to very precisely control the viscosity of that fluid. And hence the dampening properties of that shock absorber.

Van Hulle: A lot of consumers are not even going to realize that their car's equipped with this kind of stuff (fluids, etc.). Some of them have the push buttons and things like that, but in others it's just automatically happening. And it's one of those things that you have to be aware of it when you’re doing these repairs and have to have a basic understanding of it because you have to know when it's working and when it's not. And if you've got something that got hit in a wheel, you better know what's on there and what is expected when you're working on it.

Today's active suspension may require calibration for comfort and safety

Center: So, in the past, we were used to replacing shocks and struts, where you just bolt these things in and make sure everything's good and tight. Today, there may be some calibrations that have to be performed to make sure that these systems are set up properly and functioning properly. It's really interesting stuff.

Poole: Absolutely. Then we have to look at certain calibration procedures, which vary from vehicle to vehicle. In this instance, we pulled back the wiring harness and the covers. It's basically a two-wire system. We know that there's two electromagnets inside of this shock. And essentially, they're using pulse width modulation to take and modulate the current that's applied to change the viscosity of that fluid, to whatever that driver's preference happens to be. Or under those cornering situations, as mentioned, where they can stiffen up one side but let the other side stay a little more relaxed for ride quality.

And then, moving to the front of the vehicle, we do have the OEM scan tool connected. From a reference stance, of course you'd be able to look at live data for whatever's available for the vehicle. You can look at the ride height sensors to see what kind of data they're reporting and things like that, and a lot of other status information. At the same time, you're going to calibrate the suspension. There is a vehicle dynamic suspension temperature calibration routine and also a suspension height sensor calibration, which are pretty straightforward routines to run. There are also very strict requirements on the temperature calibration, as they look at getting some sort of a standardization relative to that fluid and its viscosity at a certain temperature. It's all important stuff that gets done to make sure we have a complete repair.

Fuchs: While the shock absorbers themselves didn't have to be programmed, we have to align all four ride height sensors and calibrate them and make sure they are right. BMW, for example, on each strut, there is a control unit, a slave control unit that communicates with the master inside. They also have a speed sensor so that the rate of movement on the suspension can be gauged.

Van Hulle: Vehicles are getting more and more complicated. More monitoring is required because (manufacturers) are worried about fuel economy, the safety, the comfort of the ride, and all those creature comforts that weren’t available in vehicles from the sixties.

And that's one of the things that I think we have to be aware of as we're working on these vehicles. Five years ago, what they had in these vehicles is not what they have now. While we're always talking about the EV, scans, sand the structure, some of these other little peripheral systems that we don't really think about a lot of times are also changing drastically.

Center: Hopefully everybody out there are doing pre and post scans the way they should be to catch these kinds of things because, if not, a customer could get a vehicle and as they're driving, they find that something's not right and they have to come back to the shop. And as we all know, that never goes well.

Poole: I think about the importance of all of the technologies, no matter where the work is on the vehicle, working the way as built, as designed. So, whenever that customer has that vehicle under adverse conditions where things aren't going ideal for them out on the road, there should be no compromise in anything.

Center: Right. Because the point, it's not just about performance, right? It's stability and it's all those things that are built into these vehicles to make sure that if you have to swerve, as Dirk talked about earlier, it's keeping that car stable when maneuvering in that situation. It's important stuff.

For more information and ways to ensure complete, safe, and quality collision repairs, go to: