The automotive industry has brought many challenges my way in the 45 years I have been working on vehicles. Each challenge brings with it a lesson you may not hear about in a class. It is the real-world experiences you overcome that give you the knowledge to keep moving forward and never give up. But the biggest challenge of my career was to straddle radar technology, which gave me a ride for my money and changed my “tech life” forever.

It all started back in 2015, when I got my first call to calibrate a front radar system on a Honda Accord. I had no idea what the procedures were all about and where to get the tooling necessary to perform the task. The information on my vehicle software systems did not have anything on the vehicle to address radar systems, and the tool needed was not readily available. The radar target had to be specially ordered from the dealer, which would take some time. I had decided to let that job go, figuring it would be the end of that type of job function for now. Then about a month later, I had another call for a Honda. Again, I turned the job away, thinking nothing of it because I already had enough diagnostics work to keep me busy.

Call of Duty: Radar

Another month went by, and I got a third call to calibrate a radar system. At this point, I had to seriously think about looking into this new call of duty. It just kept knocking at my door, and I knew it wasn’t going to go away. I decided to order my first radar target from Honda. When it arrived, it looked like it was assembled by parts from Home Depot, with PVC Pipe made into a stand with a metal prism perched on top (Fig. 1). I also had to ask ALLDATA to dig into the Honda factory system for which they had access for the calibration procedure, because nothing was yet in their system.

Once I did all my reading and became familiar with the calibration procedure and how to set up the target, I scheduled the vehicle in and performed my first radar calibration. It was a good feeling to take on the job and succeed with new knowledge and gain new revenue for my business. But I was unaware of what was to come. A few weeks later, I received another call for a Toyota and the good news was that the Toyota was able to be done with the same tool. But again, I had to go digging for the information because it was not available in my ALLDATA System.

As time went on, I was getting calls about once a week for just a single Honda or a Toyota, and I wasn’t thinking much of it. But then the calls started coming in twice a week. And then there were other calls for other manufacturers. The equipment for these other manufacturers was just too large to put on board my truck, and calibration information had to be retrieved every time directly from manufacturer sites because it was just not available on my information systems. I remember telling myself that someone had to design a system where one machine could do all manufacturers with all the access calibration procedures on board, similar to a front-end alignment machine, but there just wasn’t anything around at the time.

This radar tidal wave was about to hit the aftermarket industry with no tooling available through the aftermarket industry, and I needed to warn many aftermarket companies about it. I remember calling a few tool manufacturers about my industry needs but they were already aware of the situation and were working on something but in the meantime the calls were now getting to a point where I was getting 3-5 calls a week by the end of 2015. There were many jobs I had to turn away because I just did not have the large equipment the dealerships were using. So, I had decided to do the best I could by buying more small portable targets from different manufacturers to keep me in the radar arena.

But then in 2019 there was a game-changer. A manufacturer decided to make a portable advanced driver assistance (ADAS)-frame machine (target system) that would cover all manufacturers and have special ADAS software to address ALL manufacturer calibration procedures. My prayers were finally answered, and I went full speed ahead to buy the entire system. I hadn’t realized the demand would only get more intense for radar calibrations as time went on. So, fast forward to 2024, and the calls have increased to almost eight daily. And there is no stopping it. What worries me is the auto industry has now moved to put radar systems in just about all makes and models for 2024, so I believe that I will hit the saturation point soon.

The entire ADAS network affects radar calibration, so don't shortcut it

Over the past nine years, I have gained so much knowledge and experience with the hundreds of vehicles I have performed radar calibrations on. I have also gained knowledge on many other ADAS systems, but I am concentrating on radar systems in this article. The most important lesson I have learned is how critical the entire ADAS network plays as a role if you’re just doing a radar calibration. You need to understand that the ABS system is the arbitrator for the entire system in making the final decision to stop the vehicle, and the engine control system is second in line to accelerate the vehicle. The electronic steering system is the third in line to steering the vehicle. If either of these systems fail, the entire ADAS network may be suspended, and the dash will have many lights on. This is why I make it a must to perform ABS, steering or engine calibration procedures as a supplement to my ADAS calibration process.

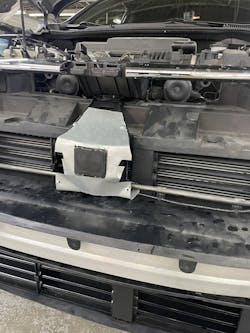

One of my biggest concerns in the field is many shops are under pressure for cycle time to get cars in and out, and we are now in such a rush that the basics are being overlooked. I educate all my shops about making three critical checks on all radar units. First is the vertical check (Fig. 2). You need to make sure that the radar unit is perfectly level top to bottom while the vehicle is on level ground, the body of the vehicle is not compromised, and the tires are properly inflated with the correct tires on the vehicle. As you can see, this radar unit is not sitting properly because it was not a priority during the reassembly process. The second check is to make sure the radar housing is horizontally level without it being tilted right to left (Fig. 3).

The last check is to check for radar housing sway using an angle finder (Fig. 4). If it’s a side radar unit, you will have to make sure both side radar units are about the same sway angle, but the front radar unit should not be swayed at all.

Begin setup with a level garage floor

When it comes to setting up your calibration equipment and the vehicle, it is important to know how to geometrically set up your equipment on your level garage floor. You always have to find the centerline of the vehicle (Fig. 5).

I do this by plumbing the front and rear vehicle emblems to the floor, laying my laser target on one end, and running my laser under the vehicle. Next you want to set up lasers in tandem to grid your floor, so you know exactly where to put your equipment (Fig. 6). This method helps to accelerate the process of getting the job done correctly.

If you are replacing the radar unit, you must ensure the correct part is installed. Some radar units may not be readily available from a dealer or are expensive. Some shops may opt to buy used parts because of the cost of these radar units. But the new issue is radar units have become hot items for thieves to steal. To combat this, one shop actually made their own anti-theft shield, but they left no holes to adjust the calibration screws (Fig. 7).

So, I had to instruct the referring shop to disassemble the vehicle and remove the shield so I could calibrate it. When buying new or used ADAS components, make sure these parts are identical to the ones you are replacing by just doing a simple visual check of part numbers and structural build. This particular Nissan I visited had the wrong grille installed. The window for the radar was missing (Fig. 8) because it was for a non-radar vehicle. Some manufacturers may require both rear side radar units be changed in pairs, especially if there is an update number that was recently released. Radar units may not be all plug-and-play and may require a secured unlock procedure, configuration file setup or in need of a programming file. This would need to be done with a factory website using a daily, monthly or yearly subscription which is not part of your ADAS software. All of this will come your way, so just be prepared.

How scan tools are changing

A lot of manufacturers are slowly moving to internet-based server access scan tools and moving away from software on a laptop for 2024 vehicles. It becomes more challenging now to service ADAS systems on 2024 vehicles with aftermarket tools, but the tool companies are trying their best to keep us in the game. I recently had to sign up with the new server-based scan tool for 2024 Lexus and Toyota Vehicles, which is the "Global TechStream Plus (GTS+)." This server-based scan tool like many others will require a two-stage based security to access by using a username and password, followed by a Google Authenticator code. Current aftermarket scan tools can’t touch the 2024 Lexus and Toyota vehicles yet. It’s all about security moving forward.

Things have really changed since the good old days of a handheld scan tool with cartridges, but you need to embrace this new technology as it knocks on your door. You can’t ignore it, or the tidal wave will sweep you away from the industry. Keep moving forward, never give up, keep on tooling and stay in the "education loop," and you will be successful.