Content brought to you by ABRN. To subscribe, click here.

What you will learn:

• Why observing a product's working time is critical

• The rule of thumb for how temperature affects the working time

• How to properly store products

For many people, summer is their favorite season. School is out, grills are fired up, and baseball is in full swing. It is also the season when temperatures and humidity rise in many parts of the country, which can significantly affect adhesives and seam sealers used in collision repair.

Application temperatures

Adhesive and seam sealer manufacturers publish windows of time for the work time, clamp time, cure time, and paint time for individual products. These times are tested for specific temperature ranges, usually about “room” temperature or 70 degrees F.

The following are some industry-standard definitions that are helpful in understanding the windows of time for adhesives and seam sealers:

During the summer, the published times can be significantly reduced. The higher the temperature, the shorter the time.

A general rule of thumb is that for every 18 degrees F increase in temperature, the open/cure time will be cut in half. (The opposite effect of temperature is true for the winter months. The published times of an adhesive will double when temperatures drop about 20 degrees.)

For example, if a product has a 15-minute work time at 70 degrees F, in the summertime when temperatures can easily reach 90 degrees F, it will start to cure twice as fast. As a result, the adhesive begins to cure before the components can be fully assembled, which is a disastrous situation for repair shop technicians.

Exceeding the working time (Figure 1) is the most common problem that results from using a product where the work time is too short to complete the job correctly.

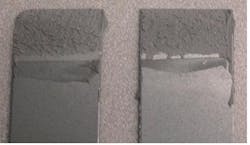

When the working time of the adhesive is exceeded, the adhesive will no longer wet out on one of the surfaces to be bonded. This will generally show up as a shiny, very smooth surface on the adhesive after disassembling the parts. A typical failure mode is cohesive failure (Figure 2), which occurs within the adhesive layer. The adhesive is pulled apart by the stress applied to the bond line. Typically, there is a fairly even split of adhesive remaining with each substrate, as shown in the photo.

To help navigate seasonal changes, shops can look for adhesives and seam sealers that have longer open times in the summer. Manufacturers often offer a family of products with a variety of times to meet the needs of higher temperatures. One example is the Fusor 123 series of non-sag seam sealer, which offers a range of work times to meet the needs of working in various temperatures throughout the year:

- Fusor 123 Fast – 3-minute work time

- Fusor 123MD Medium – 15-minute work time

- Fusor 123SL Slow – 45-minute work time

Storage temperatures

Follow the manufacturer’s recommend storage temperatures on the label. Store chemical products away from heat and sunlight.

Storage tips for the shop:

- Avoid storing chemicals on a high shelf in the shop where it may be hotter, especially during the summer months.

- Store chemical products in a closed cabinet for safety and best performance.

- Urethane adhesives are moisture-sensitive. Cartridges should be left in their Mylar bag with the desiccant until ready for use. Protect partial cartridges from moisture exposure.

Humidity

In addition to seasonal temperature changes, a geographic area with high or low humidity can also impact cure times — depending on the type of adhesive or seam sealer. One-component (1K) products cure by reacting with water in the air in addition to temperature. With higher humidity in the summer months, one-part products will experience a fairly reliable cure and may cure much slower in drier conditions during the winter months.

Two-part (2K) products have an activator which creates a chemical cure when the two resins and accelerators are mixed. These products do not rely on humidity in the air for curing, making them more predictable and less subject to fluctuations in humidity.

Choosing the right adhesive will depend on several elements, with temperature and humidity topping the list. Both are crucial considerations because they will determine which adhesive should be used based on the amount of time needed to dispense the material, mate the parts, and clamp the assembly. Evaluating current temperature and humidity levels to determine an adhesive’s cure time may seem complicated, but it doesn’t need to be.

Always follow the OEM product and procedure recommendations. Before starting a new collision repair job, technicians should obtain proper repair information and product instructions and be aware of the impact the current temperature and the humidity level will have on the outcome of the repair work.

“Understanding the climate and how it affects adhesives is just as important as identifying the proper adhesives for your application,” says Patrick Maloney, global sales and business development manager at Parker Lord.

To ensure the most appropriate adhesive is selected based on influences like climate, technicians should consult with their adhesive manufacturer and refer to the products’ technical data sheets and available training programs.

“By collaborating with the manufacturer and carefully following instructions, the result will be a quality repair that will last the life of the vehicle." Maloney adds.