There is often the expectation that a collision repair shop is going to be dirty, with dust from sanding primer and fillers, and therefore many collision repair facilities accept it as a way of life. But there is much more to consider when you envision how a shop could run if it were operating in a clean environment.

In Europe, more than 90 percent of collision shops have a dust extraction system – but fewer than one in four U.S. shops do. This is in large part due to the environmental and workplace regulations in place in Europe. Shops are required by law to use a dust extraction system and capture any dust that is produced by sanding throughout the process. Although there are certain states and cities in the U.S. that are starting to regulate the capture of dust, it is still a new concept for many parts of the country, and therefore most shops have not pursued dust extraction. For the shops in the U.S. that have tried it in the past, many found that there was technician resistance due to large hoses coming off the tools, and a lack of understanding of the value proposition of dust extraction.

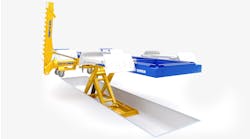

These first systems were full central vacuum systems that required a large investment and installation. These systems used a large stationary dust collector and were piped throughout the shop so that every technician had a vacuum line drop to connect to while doing their work. The other option that has gained increasing popularity are mobile dust extraction units. This type of system uses a small mobile dust extractor that can be moved around the shop from job to job and utilized by two technicians at a time. In most cases, the shop would invest in a few mobile units to equip every technician with dust extraction. The mobile option can be very practical for all size facilities due to its versatility and mobility in any part of the shop. Another dust extraction option is self-generated vacuum sanders. These types of sanders use pneumatic air and the venturi effect to pull the dust through the tool and into a dust collection bag or hose. This option does not have a high efficiency of dust collection but is a lower-cost option.

How does a shop create a clean environment?

1. Consider where the dust and dirt are coming from. When the vehicle is dropped off by the customer, most likely it is not clean. One mistake many collision repair facilities make is not cleaning the car prior to it entering the shop. Whether it is a quick rinse or an on-site car wash, cleaning the vehicle prior to repair will reduce dirt, dust, and contaminants from entering the shop.

2. Shop layout is another important factor. Grinding, sanding, painting and polishing don’t mix well. It is too easy for contaminants from one operation to migrate to another area where dirt and dust can combine. It is important that dust is contained in the area where it is generated and that particular areas of the shop are isolated by curtains and/or walls. This will help reduce extra cross-contamination from dirt and dust migrating from one area of the shop to another.

3. There is also a need to reduce the amount of dust in an air-conditioned or heated facility, otherwise the air-conditioning units and heating elements can get clogged with dust and contaminants.

4. The biggest source of dust is produced from sanding. Body filler and primer dust have a huge impact on the cleanliness of a shop. It is important to determine a dust extraction system that works for your shop layout and your technicians' needs. Whether it is a central vacuum or mobile dust extraction units, this is key to keeping a shop clean. When the shop begins using a dust extraction system, you will need to also adjust the abrasives that you use. The abrasives being used need to contain dust extraction holes that match your unit. If your shop is using adhesive-backed abrasives, you will need to switch to a hook-and-loop backed abrasive, otherwise the adhesive-backed abrasives will not stick. Now that you are using a dust-free hook and loop abrasive, you will need to optimize the system.

5. There are many applications that produce dust. The majority of dust is produced by dual-action sanders and hand blocks. Therefore, the sander and blocks need to have dust extraction capabilities. The optimized system will contain a dust extraction unit, a hose to connect the tools, a dust-free sander, dust-free blocks, an organized work center, premium dust-free abrasives and all the adapters to connect the system together.

A cleaner shop can also impact the success of a business in many other ways:

- Creates a positive overall impression for customers that can lead to new and repeat business.

- Helps increase production efficiency by reducing defects in paint work, time spent polishing, and time spent cleaning dust out of parts of the car.

- Helps reduce technicians’ time spent cleaning their work stations, allowing more time to produce work and move more cars through the shop.

What could you do with one more car out the door each day? All of these factors come in to play when considering just a few small adjustments in the way you run your shop. Consider learning about and investing in a clean shop environment this year as it can help impact your business in a big way with more productive technicians, increased production efficiency, and growing your organization in ways you didn’t imagine.

Information provided by 3M Collision